Total Factory Area : 15000 Sq.Ft

Induction Hardening Furnace

Aluminium HT Section Area

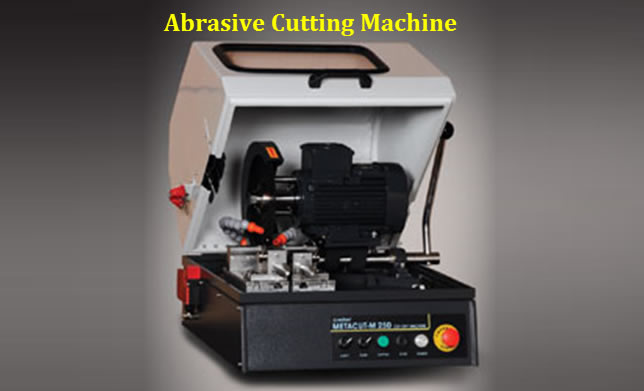

Machinery Facilities

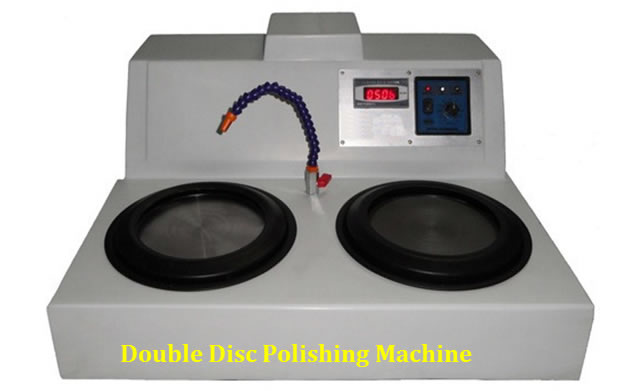

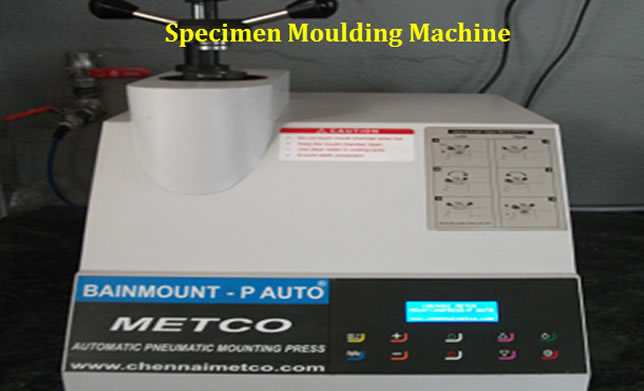

Metallurgical Laboratory

Metallurgical Laboratory

Heat Treatment Facilities

NSR Unit

Nitriding Section

Machinery Facilities

Metallurgical Laboratory

Metallurgical Laboratory

Sealed Quench Furnace

Heat Treatment Facilities

Malumichampatti Unit

Machinery Facilities

Machinery Facilities

Metallurgical Laboratory

Metallurgical Laboratory

Bottom Drop Furnace

Heat Treatment Facilities

Process Capabilities

- Annealing

- Case Hardening

- Carburising

- Carbonitriding

- Plasma & Gas Nitriding

- Hardening

- Localized Stress Relieving

- Tempering

Process Capabilities

- Liguid Nitriding

- Metallography

- Nitro Carburising

- Normalising

- Non Ferrous Treatment

- Stress Relieving

- Sub Zero Treatment

- Solution Annealing

Equipment Resources Quality Assurance

- Brinell Hardness Testing Machine – 4 Nos.

- Optical Brinell Hardness Testing Machine – 1 No.

- Rockwell Hardness Testing Machine – 5 Nos.

- Superficial Hardness Testing Machine – 1 No.

- Hydraulic Press – 40 Tons

- Power Packed Hydralic Press – 40 Tons

- Screw Press – 2 Nos.

- Shot Blasting Machine – Tumblast Type – 1 No.

- Grid Blasting Machine – 1 No.

Equipment Resources Process

- Sealed Quench Furnace – 2 Nos.

1.1250 x 650 x 620 mm – Capacity – 650 kgs - Gas Carburizing Furnace – 5 Nos.

∅700 x 2000 mm depth (500-900 kgs) - Electrically Heated Tempering Furnace – 1 No.

∅700 x 2000 mm depth - Electrically Heated Bottom Drop Furnace – 5 Nos. (for Aluminium Alloys)

1500 x 1500 x 1500 mm – 4 Nos. (0.5-1 ton)

3440 x 1950 x 1600 mm – 1 No. (2 tons) - Induction Hardening Machines

Medium Frequency – 300 KW : 3 to 10 Khz – 1 No. (Part Size Shaft -L-3 mtrs, OD-350mm / Gear-OD-2mtrs, Weight-4.5 Tons)

Dual Frequency – 100 KW : 40 Khz – 1 No.

Radio Frequency – 25 KW : 80 Khz – 1 No. - Oil Fired Pit Type Furnace – 2 Nos.

6500 x 3000 3500 mm (Part Size: L-6.5mtrs, W-3mtrs, H-3.5mtrs and weight 20 Tons) - Bogie Hearth Furnace Electrical – 5 Nos.

2000 x 1200 x 1200 mm (1.5 Tons) - Gas Nitriding – 2 Nos.

∅900 x 1350 mm (1 Ton) - Liguid Nitriding Bath – 2 Nos.

∅650 x 1200 mm (250 kgs) - Sub Zero Treatement Chamber – 1 No.

1200 x 600 x 450 mm (500 kgs) - Plasma Nitriding – 1 No.

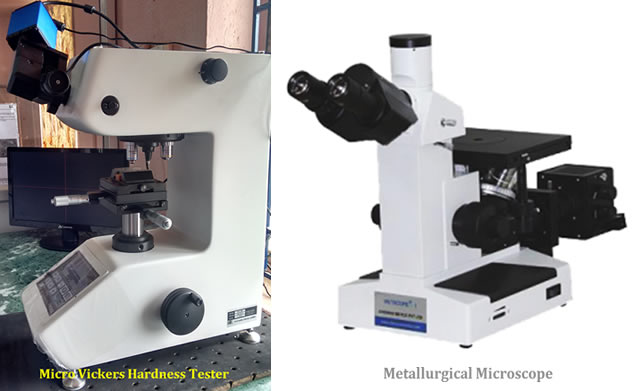

∅900mm X 1000mm Height – 110 Capacity - Micro Hardness Testing Machine (Vickers) 2 Nos.

Make : Zwik Asia Pvt. Ltd Capacity : 200 gms. to 10 Kgs.

Make : Future Tech (Japan) – 100 gms to 2 Kgs. (Semi Automatic) - Portable Hardness Testing Machine

Make : Equotip

Suitable for : HV, BHN, HRB HS Scales and Materials like steel, SGI, Cast Iron, Copper, Aluminium, Brass, Bronze and Tungsten - Poldi Hardness Testing Machine – 1 No.

- Metallurgical Microscope with USB Camera & Image Analyser – 20 Nos.

Magnification 100, 200, 400, 500 & 1000x - Chemical lab for Nitriding Bath Analysis 1 – No.

- Magnetic Particle Testing Machine with Demagnetizer 1 No.

Make: Electro Magfield Control & Services - Scada and Paper less Recorder (Data Logger) System – 6 Nos.